|

| |

Most construction procedures using heavy equipment create vibrations which can be felt, if

you are sufficiently close. However, not all vibrations are of equal concern from the standpoint of damage to a home or

structure nor are all the methods by which such equipment is used equally probable to cause damage.

Felt vibrations will not always cause damage. Most construction procedures using heavy equipment create vibrations which can be felt, if

you are sufficiently close. However, not all vibrations are of equal concern from the standpoint of damage to a home or

structure nor are all the methods by which such equipment is used equally probable to cause damage.

Felt vibrations will not always cause damage.

In this chapter of the CVDG, I summarize some typical construction operations, with with emphasis on their potential for causing vibration damage, based on my

own road construction damage experience, extensive consulting in construction vibration damage cases, and the scientific literature of vibration damage.  Some numerical estimates of relative construction equipment type vibration

potential can be found in our Vibration and Distance chapter. Some numerical estimates of relative construction equipment type vibration

potential can be found in our Vibration and Distance chapter.

Construction Operations and Vibration Potential

Those operations of the most concern are

bolded in the list below. I separate those operations which may produce felt

vibrations with low probabilities of damage from those which produce felt vibrations which may be damaging in at least some circumstances. Note that this list may not include absolutely every kind of

operation involved in road demolition and construction, or construction

generally. I provide photos of most of the equipment used as an aid for those who may not be otherwise familiar with construction heavy equipment. Some items of lesser

concern could produce damage if inappropriately performed or if your house is

particularly close to the work. Indeed, some such operations are known to have produced many

vibrations in excess of the FTA ground vibration standard

(see below).

This list is provided for those who may want to plan for documenting certain

activities around their home during construction operations. Vibrations from non-construction sources are discussed in the CVDG's Non-construction Vibrations chapter, while

background on blasting, and the vibrations stemming from it, can be found in the CVDG chapters, Blasting Vibrations and Vibration and Distance. Critical Operations

-

Pavement breaking

- This operation, if done correctly with the correct equipment at sufficient distance, is usually

not a cause for worry. Most commonly, pavement can be "rolled up" by getting

under it with a loader, dozer (e.g. video frame capture at right) or excavator bucket and raising it.

This operation generally produces

relatively little and short-lived vibration. Other types of

pulverization/cutting equipment (e.g. a Wirtgen pulverizer) can also

be properly used without much concern for excessive vibration, so long as your home is more than 50 feet away from the work. Even a

specially-designed excavator attachment can be used to roll up or

break pavement without significant risk, when it is used far enough away from homes. However, there are

other, generally non-approved, methods which can cause very large

vibrations and damage. I have personally observed and repeatedly documented on video the

use of a large excavator (e.g. the one at the top of the page) or backhoe standard bucket

to pound on asphalt pavement to break it by multiple construction firms on multiple occasions.[4] The effect of this was similar to being in a large

number of moderate size earthquakes.[10] It caused widespread and extensive damage to many homes on the street. The types of damage resulting from

at least one example of this pounding

(e.g. multiple breaks in monolithic concrete 180 feet from the work site) was such

that it implied vibration

velocities far in excess of any vibration standard worldwide.[16] Such a use of the excavator violates the

Operator's Manual instructions for the excavator in several places.[6],[13] I have also

documented pavement being broken by

picking

large chunks of it up with a loader and dropping them on the ground to break them.

This

also generated felt vibration, exceeded construction vibration standards and

created documented damage. This operation generally produces

relatively little and short-lived vibration. Other types of

pulverization/cutting equipment (e.g. a Wirtgen pulverizer) can also

be properly used without much concern for excessive vibration, so long as your home is more than 50 feet away from the work. Even a

specially-designed excavator attachment can be used to roll up or

break pavement without significant risk, when it is used far enough away from homes. However, there are

other, generally non-approved, methods which can cause very large

vibrations and damage. I have personally observed and repeatedly documented on video the

use of a large excavator (e.g. the one at the top of the page) or backhoe standard bucket

to pound on asphalt pavement to break it by multiple construction firms on multiple occasions.[4] The effect of this was similar to being in a large

number of moderate size earthquakes.[10] It caused widespread and extensive damage to many homes on the street. The types of damage resulting from

at least one example of this pounding

(e.g. multiple breaks in monolithic concrete 180 feet from the work site) was such

that it implied vibration

velocities far in excess of any vibration standard worldwide.[16] Such a use of the excavator violates the

Operator's Manual instructions for the excavator in several places.[6],[13] I have also

documented pavement being broken by

picking

large chunks of it up with a loader and dropping them on the ground to break them.

This

also generated felt vibration, exceeded construction vibration standards and

created documented damage.

Rock and concrete breaking - When not done by blasting, rock and concrete are usually broken for removal with hydraulic rock breakers, also called "hoe rams".[22]

Hoe rams are attachments typically mounted on the end of an excavator or backhoe arm. They have a pointed tip which actually does the breaking by, in essence, pounding the tip on the rock or concrete (see photo right). Hoe rams can generate vibrations

which can be damaging to homes, if sufficiently close.[15] When large amounts of rock must be moved (e.g. for a road or pipeline), construction blasting is usually employed. See

below for more on the damage potential of blasting. Rock and concrete breaking - When not done by blasting, rock and concrete are usually broken for removal with hydraulic rock breakers, also called "hoe rams".[22]

Hoe rams are attachments typically mounted on the end of an excavator or backhoe arm. They have a pointed tip which actually does the breaking by, in essence, pounding the tip on the rock or concrete (see photo right). Hoe rams can generate vibrations

which can be damaging to homes, if sufficiently close.[15] When large amounts of rock must be moved (e.g. for a road or pipeline), construction blasting is usually employed. See

below for more on the damage potential of blasting.- General demolition - Demolition has the potential to cause

damage, because many of the vibrations it produces are of the ground impact

variety. Ground impacts produce

ground vibrations with a broad spectrum of frequencies that overlap the

resonance frequencies of homes. The damage potential of demolition depends

on the procedures and equipment used, the type of structure or material demolished, and

the skill and concern with which it is done.

-

Pile driving - There are several different methods for pile driving and several different types of piles.

Impact (hammer) pile drivers are known to cause large and potentially damaging vibrations.[18] Vibratory and sonic (resonance) pile drivers, despite the names, generally produce

much less ground vibration than impact pile drivers,[2],[11] although even they can be a

problem if your home is sufficiently close. In cases where structures are within 100 feet of the pile site, hammer pile drivers should not be used.

Sonic (resonance) pile driving can have well over a factor of ten lower

vibration generation than hammer pile driving. It is usually considerably faster than impact pile driving, thus reducing further the total amount of vibration created. It should be used in place of hammer pile driving whenever vibration damage of any sort is possible.[11]

-

Compaction

- Compaction is the single most-cited damage-causing operation among those reported to Vibrationdamage.com. There are two basic kinds of continuous compactors ("rollers"), vibratory and oscillatory, as well as those which combine vibration and oscillation (so-called VO types).[17]

Both vibratory and oscillatory compactors can be used in static mode, without vibration

or oscillation. Static compaction merely rolls the asphalt or ground and has less damage

potential than compactors using vibration.

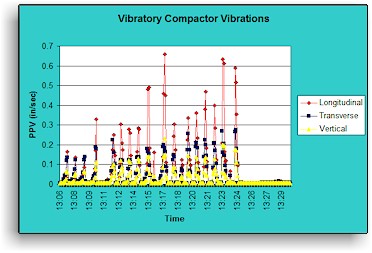

Vibratory compactors (e.g. at right) transmit substantial vertical vibrations to the ground, which can cause damage in our experience

(vibration record of a small portion of one day's compaction operations at left). Oscillatory compactors are newer types which use side-side oscillation in place of most of the up-down vibration. They produce lesser

vibration for the same degree of compaction.[14] The amplitude (intensity) of the compactor vibration can be varied over a wide range by the compactor operator, causing the ground vibration to vary as well.

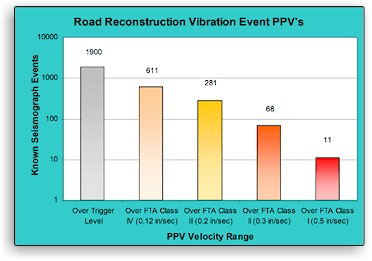

There are many other factors which affect vibration ground velocities produced by vibratory compactors. Vibratory compactors are of sufficient concern that the Federal

Transit Administration has advised against their use in "sensitive"

locations, including residential areas.[1] As the diagram at left shows, the contractor violated

some or all FTA construction vibration standards (starting at 0.12 in/sec

for structures sensitive to vibration and going up to 0.5 in/sec for reinforced,

engineered structures) numerous times during

vibratory compaction at this and other locations.[7],[8]

In this example and others, a road construction contractor also repeatedly exceeded the far less demanding USBM RI 8507 blasting vibration recommendation of

0.5 in/sec for homes

with plastered walls.[5]

If you can feel vibrations occurring as a compactor approaches, chances are that a vibratory or oscillatory compactor is responsible.[9],[12] You will need to observe and document carefully the use of the compactor and any damage that may occur during its

use. Vibrations from vibratory compaction are discussed in considerable detail in our

Vibration and Distance chapter. The CVDG Pro page, Damage Occurrence, has a statistical breakdown of CVDG downloads by reason

for download, technical backgrounds of damage reporters, building types, construction project type, damage-causing operations, and more. Vibratory compactors (e.g. at right) transmit substantial vertical vibrations to the ground, which can cause damage in our experience

(vibration record of a small portion of one day's compaction operations at left). Oscillatory compactors are newer types which use side-side oscillation in place of most of the up-down vibration. They produce lesser

vibration for the same degree of compaction.[14] The amplitude (intensity) of the compactor vibration can be varied over a wide range by the compactor operator, causing the ground vibration to vary as well.

There are many other factors which affect vibration ground velocities produced by vibratory compactors. Vibratory compactors are of sufficient concern that the Federal

Transit Administration has advised against their use in "sensitive"

locations, including residential areas.[1] As the diagram at left shows, the contractor violated

some or all FTA construction vibration standards (starting at 0.12 in/sec

for structures sensitive to vibration and going up to 0.5 in/sec for reinforced,

engineered structures) numerous times during

vibratory compaction at this and other locations.[7],[8]

In this example and others, a road construction contractor also repeatedly exceeded the far less demanding USBM RI 8507 blasting vibration recommendation of

0.5 in/sec for homes

with plastered walls.[5]

If you can feel vibrations occurring as a compactor approaches, chances are that a vibratory or oscillatory compactor is responsible.[9],[12] You will need to observe and document carefully the use of the compactor and any damage that may occur during its

use. Vibrations from vibratory compaction are discussed in considerable detail in our

Vibration and Distance chapter. The CVDG Pro page, Damage Occurrence, has a statistical breakdown of CVDG downloads by reason

for download, technical backgrounds of damage reporters, building types, construction project type, damage-causing operations, and more.

-

Blasting - It is well-known that blasting vibration can damage structures

to varying degrees. Indeed, much of the scientific literature about

vibration damage deals with damage caused by blasting. Although blasting is

usually done in mines and quarries and, to a lesser extent, in construction, it must be done properly and at sufficient distance from

structures to avoid damage. Construction blasting ground vibrations often differ in important ways from mine and quarry blasting vibrations, so conclusions from studies of mine and quarry blasting vibration studies do not always carry over well to

construction blasting. They certainly do not carry over to long-duration and repeated construction vibrations. All blasting produces vibrations which have a broad range of frequencies. USBM RI 8507 has extensive comparisons of vibrations from these three different types of blasting.[5] See our

Vibration and Distance and Blasting Vibrations chapters for more discussion of blasting vibrations.

-

Crack-and-seat operations - This operation involves using a large heavy equipment-mounted hammer or weight dropped on pavement to crack it. The pavement pieces are "seated" in the

sub-grade by compaction and then paved over. This method of pavement rehabilitation can produce very large ground vibrations close to the operation (within 100 feet typically).[21]

Other Operations

-

Pavement milling - This is a process by which pavement is ground off in small, gravel-like pieces (see at

right above for a photo of a pavement miller in use) with rotating blades, rather than

broken apart in large chunks by impact. It usually produces a small amount of non-damaging

vibration. That said, because pavement millers are tracked vehicles removing

pavement by impact and moving at a slow rate in front of any given location,

their use should probably not be completely disregarded as a vibration damage source in

at least some circumstances. Pavement milling - This is a process by which pavement is ground off in small, gravel-like pieces (see at

right above for a photo of a pavement miller in use) with rotating blades, rather than

broken apart in large chunks by impact. It usually produces a small amount of non-damaging

vibration. That said, because pavement millers are tracked vehicles removing

pavement by impact and moving at a slow rate in front of any given location,

their use should probably not be completely disregarded as a vibration damage source in

at least some circumstances.

- Excavation - Excavation can be done with backhoes or excavators (often referred to as "track hoes"). In our

experience, and also that reported in the scientific literature, excavation alone usually causes vibrations of low velocity. It can be of much greater concern if the ground to be excavated is particularly hard or rock-laden.

- Dirt moving - This can be done with a wide variety of heavy equipment, such as graders and dozers.

It usually produces little or no vibration or damage, if properly done.

- Pavement forming - This is the process of continuously laying down the pavement. It

involves a pavement former (as at right) and trucks which provide a continuous supply of

asphalt to the pavement former.

In our experience, pavement forming produces only minor vibrations, which do not normally generate damage at distances of more than 50 feet from structures.

Subsequent compaction of the formed pavement is

far more likely to produce damaging vibrations. In our experience, pavement forming produces only minor vibrations, which do not normally generate damage at distances of more than 50 feet from structures.

Subsequent compaction of the formed pavement is

far more likely to produce damaging vibrations.

- Jack-hammering - This procedure is often used in road projects, as well

as many others. Perhaps surprisingly, the vibrations created are so localized that

they can't normally be felt if you are more than 50 feet away. Jack hammers are different from hoe ram rock breakers in that they are handled by a worker directly, not mounted on the end of a backhoe or excavator, as hoe rams

are. As indicated above, hoe rams have considerably more potential for creating damage if used too close to homes.

-

Other operations - Grading, sweeping, concreting, curb installation,

manual operations and a host of other activities can take place during road

building or other construction activities. Although there could be

exceptions in specific cases, all of these are usually of little worry, if

carried out properly and in accordance with accepted procedures for use of

the equipment. Similarly, construction operations done by people using only

hand tools pose little risk of damage in most circumstances. Other operations - Grading, sweeping, concreting, curb installation,

manual operations and a host of other activities can take place during road

building or other construction activities. Although there could be

exceptions in specific cases, all of these are usually of little worry, if

carried out properly and in accordance with accepted procedures for use of

the equipment. Similarly, construction operations done by people using only

hand tools pose little risk of damage in most circumstances.

Heavy Tracked Equipment Movement

While

not a construction operation, per se, limited movement of heavy equipment is a

part of any construction project. Indeed, tracked excavators and dozers must move

small distances (usually well under 100 feet in any one movement) to perform their work at a given

location. These short distance moves in the normal

and approved use of heavy equipment generally present small risk to

structures.

Tracked heavy equipment is supposed to be transported larger distances on trailers. However, we've observed and documented on

video several instances (e.g. the video frame capture at right of an excavator moving along a city street) where tracked heavy

equipment was being driven on a city street for a mile or more. That movement caused

so much vibration in homes that it could be felt more than a half block away and

continued for more than a minute in each such location. I

documented damage specifically caused by those movements. Tracked heavy equipment is supposed to be transported larger distances on trailers. However, we've observed and documented on

video several instances (e.g. the video frame capture at right of an excavator moving along a city street) where tracked heavy

equipment was being driven on a city street for a mile or more. That movement caused

so much vibration in homes that it could be felt more than a half block away and

continued for more than a minute in each such location. I

documented damage specifically caused by those movements.

The intensity (peak particle velocity) of ground vibration associated

with movement of tracked equipment is often relatively small and within

some construction

vibration standard limits. For this reason, it is commonly discounted

as a damage source. However, as described in detail in the CVDG Pro chapters,

Vibration Signatures, and in abbreviated form on the CVDG page,

Is Damage Possible?, because the vibration frequency distribution generated by tracked equipment movements is skewed toward

frequencies close to the

resonant frequencies of the home and because the vibration created can last for a minute or more, such long distance driving of tracked equipment can be particularly ill-advised.

Although

tracked equipment movement is rarely a subject of vibration damage studies, a study from the U.K.[3]

shows that driving large tracked vehicles of the sort used in road construction

(large bulldozers, excavators)

can produce vertical axis ground vibration accelerations in excess of those

caused by vibratory compactors. Higher accelerations mean higher final ground

vibration velocities (higher peak particle velocities, PPV's) over any given time period. Vibratory compactors, themselves, are known to violate some U.S.

and international construction

vibration velocity standards, if close enough to structures.

Vibrations produced by driving tracked equipment often have

peak frequencies in the sub-40 Hz range of most concern for damage effects. The U.K. study demonstrates that such vibrations

from driving tracked equipment

are of special concern, especially when repeated or lasting a significant period of time

(more than a few seconds),

even though they were not suspected to be capable of causing "architectural" (cosmetic) damage at the time of the study cited

(1977), when vibration standards set far higher limits than are acceptable today. A more recent U.S. study confirms the damage potential of driving tracked equipment over significant distances.[15]

Tracked equipment vibration levels are known to vary with the weight of the tracked equipment, the

speed at which the equipment is driven, the underlayment (soil/type and/or pavement) and

the type of track (standard or low-vibration track patterns, metal or rubber

tracks) on the equipment. The U.K. study also shows that rubber-tired vehicles

usually produce little vibration above background levels. My own observations of movement of a wide variety of rubber-tired construction equipment, and other vehicles, in a road reconstruction project are consistent

with that finding. Thus, it is tracked

equipment whose movement over distances should be monitored for vibration, not

only with respect to the largest vibration produced, but with careful

consideration of both its duration and frequency distribution.

Vibrations in One Road Construction Job  Vibrations over construction vibration standards can occur frequently and repeatedly in some construction

jobs. The measured PPV's at the dominant frequency for a partial set of vibration monitoring data, involving a 6 month long road reconstruction/water main replacement job,

are shown in the graphic at left. Even given the extensive and important omissions in the data,[19] there were literally hundreds of

violations of construction vibration standards in these data, which reflect vibrations from most types of road construction operations involving heavy equipment. Several vibrations exceeded all U.S. FTA construction velocity limits. The majority of these vibrations also had dominant frequencies

below 40 Hz (i.e. in the frequency regime with the greatest probability of causing damage, see Resonance and Fatigue for more on this point). While these data can't be said to be completely representative of all road construction operations, both because of the data omissions

-

involving mostly examples of vibratory compaction and pavement demolition -

and possible differences in the amount of vibration attenuation from this locale relative to others, they show that road work with

typical mix of heavy equipment has considerable potential

for exceeding standard velocity limits and creating damage, especially when done in close proximity to homes and other structures.[20] Vibrations over construction vibration standards can occur frequently and repeatedly in some construction

jobs. The measured PPV's at the dominant frequency for a partial set of vibration monitoring data, involving a 6 month long road reconstruction/water main replacement job,

are shown in the graphic at left. Even given the extensive and important omissions in the data,[19] there were literally hundreds of

violations of construction vibration standards in these data, which reflect vibrations from most types of road construction operations involving heavy equipment. Several vibrations exceeded all U.S. FTA construction velocity limits. The majority of these vibrations also had dominant frequencies

below 40 Hz (i.e. in the frequency regime with the greatest probability of causing damage, see Resonance and Fatigue for more on this point). While these data can't be said to be completely representative of all road construction operations, both because of the data omissions

-

involving mostly examples of vibratory compaction and pavement demolition -

and possible differences in the amount of vibration attenuation from this locale relative to others, they show that road work with

typical mix of heavy equipment has considerable potential

for exceeding standard velocity limits and creating damage, especially when done in close proximity to homes and other structures.[20]

Vibration and Damage Structures respond differently to vibration and have different damage thresholds, as well as different responses to differing vibrations generated by different means. The materials of construction, the building design, its age and its

level of maintenance are some of the important determinants of vibration damage resistance. The CVDG chapter, Vibration and Damage, discusses building design and construction type influences on the

potential for damage by vibration. Most kinds of construction operations with heavy equipment have very low probabilities of damage to homes, if done properly. Work of these types can usually be safely tolerated. However,

a few such operations, particularly blasting, pile driving, rock breaking, demolition, and movement of heavy equipment for more than a few seconds, constitute a larger potential risk of damage to structures. They should be

carefully observed and documented in any job in which they are done.

[1] Transit Noise and Vibration Impact Assessment, Carl E. Hanson, David A. Towers, and Lance D. Meister, FTA-VA-90-1003-06, May 2006 (Federal Transit Administration's Noise and Vibration

Manual) ,

p. 12-14

↩

[2] Ibid.,

p. 12-12

↩

[3] Ground Vibrations Caused by Road Construction Operations, D J Martin, Department of the Environment,

Department of Transport, TRRL

Supplementary Report 328: Crowthorne, 1977

↩

[4] Even properly done pavement breaking can be dangerous to homes: "With

the exception of a few instances involving pavement breaking, pile

driving, all Caltrans construction vibration measurements have been

below the 5 mm/s (0.2 in/sec) architectural damage risk amplitude for

continuous vibrations. The highest measured vibration amplitude was 73.1

mm/s (2.88 in/sec) at 3 m (10 ft) from a pavement breaker." (Transportation-

and construction-induced vibration guidance manual. June 2004.

California Department of Transportation, p. 15)

↩

[5] Structure Response and Damage Produced by Ground Vibration From Surface Mine Blasting, D. E. Siskind, M. S. Stagg, J. W. Kopp, and C. H. Dowding, United States Bureau of Mines Report of

Investigations 8507 (USBM RI 8507), 1980, p. 58

↩

[6] Caterpillar Operation and Maintenance Manual, 320 B, 320 B L, and 320 B N Excavators, SEBU 6075-07, p. 31, p. 101, p. 106, among others. Obtainable in PDF format by online purchase from Caterpillar

↩

[7] Because these vibratory compaction data show such high peak particle velocities, some further information is in order. The vibration monitoring technician did not record, photographically or textually, the location of the

seismograph at the address he cited for these data, with respect either to the house, the work, or any other fixed landmark, nor did he record the distance from the instrument to the compaction operation. However, other photos taken that day by the vibration technician of the compaction operation show that the point of closest approach to the

seismograph was at least 17 feet away from the vibratory compactor (based on Google Earth measurements of the site and the photos taken) when the 0.66 in/sec PPV in this diagram was recorded. The point of closest compactor

approach to the home was, at most, 48 feet from the home, based on the same measurements. In the 33 minute period of monitoring at this date and location, there were 58 vibration events over FTA vibration standards, only a

portion of which are shown in the graphic record above. These data involved compaction of a first layer of asphalt over compacted soil (type classified as silty sand), using an Ingersoll-Rand DD-70HF vibratory compactor with a specified front drum static weight of

7,410 lb. (33 kiloNewtons, kN), a rear drum static weight of 7,485 lb. (33.4 kN) (from published specifications), and an unknown operator-chosen vibratory

amplitude (intensity) at a nominal vibration frequency of 66.7 Hz. The centrifugal force range for this compactor is 7,820 – 21,080 lb (35 – 94 kN) (from published specifications).

The PPV's of all vibrations from compaction of a second layer of asphalt the next day in the same lane at the same address are not known. The relevant

histogram data were among those "lost" by the vibration technician and the contractor, without any credible explanation for the loss of these and most other critical paving vibration data. The seismograph monitor log for the second day at that site shows 6 events occurring in the first 2 minutes of a 20 minute

installation, before event

recording stopped when seismograph event memory filled. The largest of the recorded events, one minute into the installation period had a PPV of 0.320 in/sec, already in violation of the FTA standard for frame homes of 0.2

in/sec, with the FFT dominant vibration frequency at 40 Hz and

other component frequencies below 40 Hz. However,

compaction in the same lane at other locations on the same street that second day, for which histogram data were not "lost", resulted in maximum PPV's which were generally 0.15 to 0.2 in/sec

higher than those recorded the previous day for the same lane of paving over soil at or near the same locations. There were a correspondingly higher number of events recorded. Thus, it is a reasonable expectation that, if the data had not been "lost" by the

vibration technician, the contractor and the contractor's "experts",

they would likely have shown a PPV of

at least 0.8 in/sec on this second day of vibratory compaction, exceeding all current U.S. blasting vibration standards, as well as all U.S. construction vibration standards.

There were at least two later

paving days along the street in question, as shown by subcontractor documents produced in litigation, but the contractor did not do any vibration monitoring for this later paving. The contractor stopped all monitoring at

least a month before the completion of the job, as admitted in sworn testimony, in spite of the clear violations of vibration standards caused by its work.

↩

[8] "Starting and stopping of the vibratory compactor may temporarily increase the ground vibration... If there is any risk of damage to buildings, low amplitude or even static compaction should be used."

Vibration Problems in Structures: Practical Guidelines, Hugo Bachmann, et al., Birkhäuser, 2012, ISBN-13: 978-3764351489, pp. 136-137. A manufacturer of vibratory compactors, Dynapac,

indicates that the minimum safe distance from structures in meters is 1 to 1.5 times the drum module weight in metric tons. (see

https://www.dynapac.co.uk/en/knowledge/End-user-Support/Soil-Applications/ (go to https://dynapac.co.uk, choose Knowledge, then End-user-Support,

then Soil Applications, if the direct link fails). The Dynapac recommendations arise from studies by Forssblad, based on a PPV limit of 5 mm/sec (0.2 in/sec), Forssblad, L., Vibratory soil and rock fill compaction, Robert Olsson

Tryckeri AB, Sweden (1981)

↩

[9] Vibratory compactors are the most commonly used equipment for pavement and soil compaction. However, pneumatic rollers (rubber-tired rollers) and combination rollers (rollers with a steel drum on one axle and tires on the other)

are also employed. Such rubber-tired rollers are usually of less concern for vibration generation than vibratory compactors. More recently, compactors which use oscillatory (side/side) drum motions, alone or

in addition to vibratory motions (up/down), have appeared. Such compactors can produce lesser vibrations for the same degree of compaction than all-vibratory compactors (see Ambient vibration of oscillating and

vibrating rollers, J Pistrol, F. Kopf, D. Adam, S. Villwock, W. Völkel, Vienna Congress

on Recent Advances in Earthquake Engineering and Structural Dynamics 2013 (book), p. 6). Once must look at the specifications for the compactor of interest to determine the specific type and frequency of vibration.

For pile driving in soil only, a hydraulic pile driver can sometimes be employed. A hydraulic pile driver uses water pressure to erode the soil under the pile, allowing the pile to sink into the ground. The water

used is vacuumed away continuously while the pile is set. There is little information available on vibrations from hydraulic pile driving, but, since it does not involve ground impact, such vibrations should be relatively

low in velocity.

↩

[10] An excavator very similar to the one referred to on this page (a Caterpillar 320 B L) has been used to simulate earthquakes by pounding on pavement: "Soon after, a PC750LC excavator shocked attendees by pounding its massive claw into the pavement and creating a "did you feel that?"

earthquake

moment[.]", The Santa Clara Weekly, March 2011, Issue 10, Out With the Old: In With the New,

https://www.santaclaraweekly.com/2011/Issue-10/quakes_stadium.html

↩

[11] Sonic Pile Driving: The History and the Resurrection of Vibration Free Pile Driving, Matthew Janes,

https://www.resonancetechnology.ca/res%20driver%20history%20090112.pdf.

↩

[12] Vibratory compactors usually cannot used to compact asphalt on bridges, due to the potential for vibration damage to the bridge. Oscillatory and vibratory-oscillatory compactors are claimed by one

manufacturer (Hamm) to be safe for pavement compaction on bridges, because of the lower vibration they produce for a given degree of compaction. Other compactor manufacturers (e.g. Caterpillar, Dynapac and Bomag) also

produce oscillatory and/or vibratory-oscillatory models now.

↩

[13] Since the publication of both versions of the CVDG, several others around the world have reported to me similar use of an excavator pounding on pavement for demolition. To date, all of those

who reported it have also

reported damage which they attribute to the pounding. The damage effects seen imply vibration velocities far in excess

of any worldwide ground vibration standard (see Recognizing Damage for more on this topic).

↩

[14] Ambient vibration of oscillating and vibrating rollers, J. Pistrol, F. Kopf, D. Adam, S. Villwock, W. Völkel, Vienna Congress on Recent Advances in Earthquake Engineering and Structural Dynamics 2013 (VEESD

2013), C. Adam, R. Heuer, W. Lenhardt & C. Schranz (eds) (available online)

↩

[15] Ground Vibrations Emanating from Construction Equipment, R. M. Lane and K. Pelham, New Hampshire Department of Transportation, Report # FHWA-NH-RD-12323W, 2012, p.

9.

↩

[16] While there are no known published measurements of ground vibration velocities from powered excavator pavement pounding, one paper (Construction vibrations: State-of-the-art, J. F. Wiss, Journal of the Geotechnical Engineering

Division, American Society of Civil Engineers, 1981, 107(2):167–181) provides velocity/distance data

for unpowered dropping of a 1.5 ton steel ball (approximately equivalent in weight to a granite boulder about 3 feet in diameter) a distance of ten feet. The recorded ground vibration velocity at 40 feet was 2 in/sec (ten times the FTA Class III standard for homes of 0.2 in/sec

at 25 feet). This is comparable to the velocity

recorded for a 1 pound dynamite explosion at the same distance (2.5 in/sec) and is higher than any other non-blasting construction operation, including pile driving. The recorded velocity at 25 feet (the FTA reference

distance) was 3.5 in/sec. In the case of the documented excavator pounding above, using the known vibration velocities required to break monolithic concrete and the distance at which the concrete was

broken in this excavator pounding example (180 feet from the work site), we can use the Vibrationdamage.com Ground Vibration PPV and Safe Distance Calculator to calculate the pounding-caused vibration velocity at 25

feet, the FTA reference distance. The result is a minimum of approximately 10 in/sec, remarkably in harmony with such estimates in the OSM Blasting Guidance Manual.

Such velocities are consistent with the widespread damage done by the excavator pounding. They can also help rationalize the damage seen when boulders are indiscriminately dropped near homes for use as rip-rap

along water courses.

↩

[17] Although continuous compaction methods are most widely used, there is another method used to improve soil compaction called "dynamic compaction". This involves

using a crane to drop a heavy steel plate or ball from a height onto the ground surface repeatedly, compacting the ground in the area of the impact. At the FTA reference distance of 25 feet, Mayne (Ground Vibrations

During Dynamic Compaction, P. W. Mayne, ASCE Soil Dynamics Committee Convention, Detroit, MI, October, 1985) reported PPV's ranging from 0.5 to 5 in/sec from 12 dynamic compaction sites. The weights varied from 4 to 40 tons and

drop heights from 5 to 100 feet in this study. Most of these vibration velocities are far in excess of any U.S. construction limit at that distance. Thus, with respect to ground vibration produced, dynamic compaction cannot be safely used closer than 100 feet

from structures.

For more, see Geotechnical engineering circular no. 1: Dynamic compaction, R. G. Lukas, FHWA-SA-95-037, Federal Highway Administration, Washington, DC. (1995)

↩

[18] Allowable Distance from Impact Pile Driving to Prevent Structural Damage Considering Limits in Different Standards, Amir Hamidi, Abtin Farshi, Homayoun Rooz, and Majid

Pourjenabi, Pract. Period. Struct. Des. Constr., 23(1): 04017029, 2018

↩

[19] These data are incomplete, because the contractor and all its consultants "lost" the overwhelming majority of data for the paving/compaction operations. Those data which were

produced for the paving/compaction showed the highest PPV's measured. No data at all were recorded for the most intense vibrations, caused by asphalt demolition by pounding on it with an excavator bucket, despite

the requirement for vibration monitoring in the contract for the work. Many

homes were damaged by this project, as documented by over 2000 photos and 14 hours of videotape.

↩

[20] Manufacturers of heavy equipment for construction use could help considerably reduce the risk for damage by providing specifications for typical vibration velocities produced

by each equipment type and model thereof which they manufacture. With such data, more accurate estimates of expected vibrations at any distance could be made, thereby allowing contractors to avoid most damage claims

by knowing in advance where problems are most likely to occur. Such typical velocities could be measured in a few hours for each model at the FTA reference distance of 25 feet, at a per unit cost of a few hundred dollars maximum.

Vibratory compactors and other equipment with variable source energies should have minimum and maximum vibration amplitude velocities specified, including those for startup and stop (or reverses in direction). The only other piece of information needed to use those data

properly would be a

one-time determination of the attenuation exponent for the soil (see Vibration and Distance) on which the vibration measurements were made, which could be measured for the site by a single set of measurements of vibrations by multiple seismographs

installed at different distances.

↩

[21] Crack

and Seat

Method of

Pavement Rehabilitation, Amy M. Schutzbach, Transportation Research Record,1215,

197. Caltrans has reported a crack-and-seat reference vibration velocity of 2.4 in/sec at 25

feet. (Transportation and Construction Vibration Guidance Manual, Jim Andrews, David Buehler, Harjodh Gill, Wesley L. Bender, California Department of Transportation, Division of Environmental Analysis,

Environmental Engineering, Hazardous Waste, Air, Noise, & Paleontology Office, Sacramento, CA, 2013, p. 37)

↩

[22] In addition to "hoe ram" and "hydraulic rock breakers", I find the same equipment described as "hydraulic hammers", "backhoe-mounted hammers", "rock breakers", "demolition tips",

"jack hammers" and similar terms. Hoe rams differ from jackhammers in their mounting on and use with heavy equipment, as well as their greater power and damage potential.

↩ |

|

|

This is a chapter from the Construction

Vibration Damage Guide for Homeowners (CVDG), a 100+ page free

book with over 300 color photos, diagrams and other illustrations.

It is available at

https://vibrationdamage.com as a series of web pages or in full,

web navigation and ad-free,

as a downloadable PDF e-book, with

additional content not available on the web. The free

version of the CVDG is licensed to homeowners and others for

personal, at-home use only. A Professional Edition (CVDG Pro), licensed

for business use and with over three times as much content, can be ordered from our

Order the CVDG Pro page, usually with same-day delivery. You can comment about this page or ask

questions of the author, Dr. John M. Zeigler, by using our Visitor Comment

form. This is a chapter from the Construction

Vibration Damage Guide for Homeowners (CVDG), a 100+ page free

book with over 300 color photos, diagrams and other illustrations.

It is available at

https://vibrationdamage.com as a series of web pages or in full,

web navigation and ad-free,

as a downloadable PDF e-book, with

additional content not available on the web. The free

version of the CVDG is licensed to homeowners and others for

personal, at-home use only. A Professional Edition (CVDG Pro), licensed

for business use and with over three times as much content, can be ordered from our

Order the CVDG Pro page, usually with same-day delivery. You can comment about this page or ask

questions of the author, Dr. John M. Zeigler, by using our Visitor Comment

form.  If you would like to discuss vibration damage issues and view additional content not found in the CVDG, Join

us on Facebook. Please Like us while you're there. If you would like to discuss vibration damage issues and view additional content not found in the CVDG, Join

us on Facebook. Please Like us while you're there. |

| |

|